When discussing metal manufacturing, one common question arises: how is die casting different from regular casting? Engineers and procurement teams often compare these two methods to determine which fits their technical and budget needs. Regular casting generally relies on gravity or low-pressure processes, allowing molten metal to fill a mold slowly. In contrast, die casting relies on injecting molten metal into hardened steel dies at high pressure. This distinction directly influences surface quality, dimensional accuracy, consistency, and production efficiency. When a die casting manufacturer explains these differences, they often highlight how pressure-based filling results in finer details and tighter tolerances than conventional casting methods. These factors shape the performance expectations across industries such as thermal management, structural components, and precision assemblies.

Why High-Pressure Metal Injection Changes the Manufacturing Equation

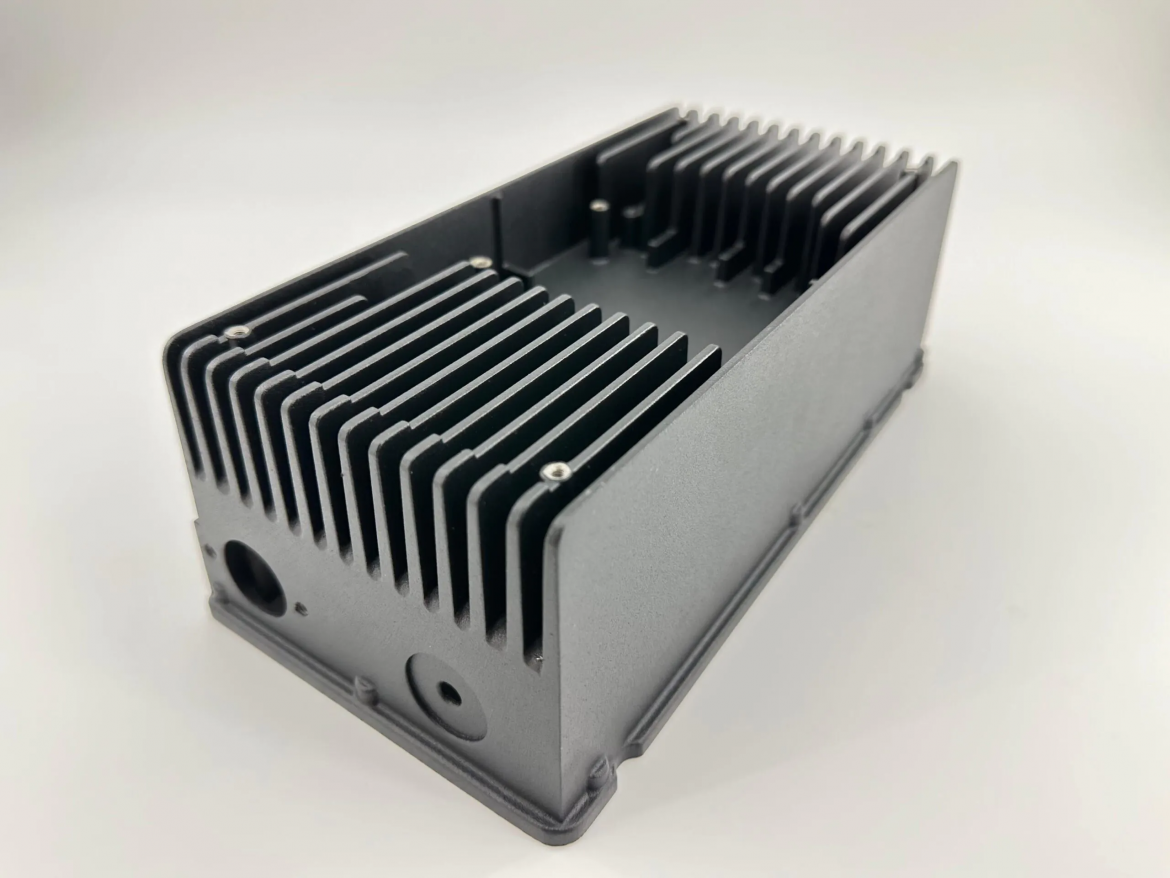

The defining characteristic of die casting is its controlled, high-pressure injection system. This method forces molten metal into complex cavities, enabling the production of detailed parts that would be difficult to form with regular casting. Compared with gravity casting, which may present variations in density and surface finish, die casting offers greater uniformity and repeatability. A reliable die cast supplier focuses on stability and precision, ensuring that each part meets strict specifications across multiple batches. For teams evaluating thermal modules, enclosures, or mechanical frames, such repeatability is essential.

Die casting also supports higher-volume production because pressure filling reduces cycle times and increases mold utilization efficiency. Regular casting often requires longer cooling periods and manual processes, leading to slower throughput. This difference is why companies planning for continuous supply chains frequently consider whether high-pressure die casting aligns better with long-term production goals.

How Dingmetal Applies Die Casting to Real Manufacturing Requirements

They approach die casting with a focus on consistent performance, making Dingmetal a practical reference when comparing these processes. As a die casting manufacturer, they emphasize how high-pressure injection strengthens dimensional accuracy and reduces the need for secondary operations. Their manufacturing teams also understand that die casting differs from regular casting not only in pressure levels but also in how it supports complex geometries that require reliable repeatability.

A smooth transition into product insight shows how this process works in real applications: Die casting involves injecting metal into specialized molds, known as dies, under high pressure. It allows for the mass production of complex metal parts with exceptional dimensional accuracy, smooth surfaces, and consistent quality. It is particularly cost-effective for high-volume production runs, typically over 1,000 units, where reduced unit prices and shorter cycle times can offset the initial tooling and Non-Recurring Engineering (NRE) costs.

They apply this principle in OEM and ODM production. At this stage, a dependable die cast supplier ensures that intricate designs and tight tolerances are achievable without extensive machining. Their advanced manufacturing capabilities help minimize post-processing, supporting engineers who need reliable components for electronics housings, thermal structures, and mechanical assemblies.

Conclusion: Key Takeaways When Comparing Die Casting With Regular Casting

Understanding how die casting is different from regular casting helps teams choose the right method for long-term projects. Regular casting works well for thicker, less complex parts produced in lower volumes. Die casting, however, uses high-pressure metal injection to achieve greater accuracy, smoother surfaces, and stronger repeatability. These differences explain why many companies turn to pressure-based methods when they require stable outputs and predictable performance.

They illustrate how die casting supports intricate shapes, faster production cycles, and reduced secondary work, making the method suitable for cost-efficient, large-scale manufacturing. With their experience as both a die casting manufacturer and a global die cast supplier, Dingmetal demonstrates how high-pressure casting aligns with modern engineering demands across metal components, structural parts, and thermal assemblies.