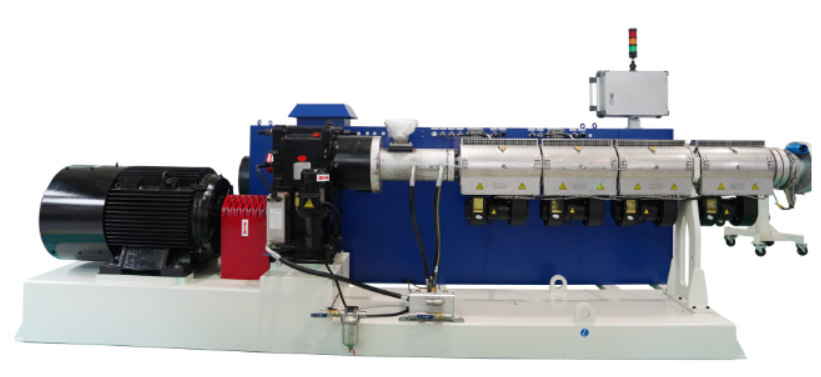

In the fast-paced world of manufacturing, DEKUMA stands at the forefront of innovation with its reliable machinery designed for single screw pipe extrusion. Known for delivering high-quality solutions, DEKUMA integrates an Intelligent Control System With a Siemens PLC and PROFINET into its single screw extruder flexible pipe machine, providing seamless control and optional data access for efficient and intelligent production management.

Intelligent Control for Enhanced Efficiency

DEKUMA’s single screw extruder flexible pipe machine features an Intelligent Control System With a Siemens PLC and PROFINET. This advanced system enables manufacturers to manage their production processes with unparalleled efficiency. The seamless control offered by this system, along with optional data access, allows for real-time monitoring and adjustments, significantly enhancing production management. One of the standout features of DEKUMA’s machinery is single screw extruder flexiable pipe machine.As a result, businesses can optimize their operations, leading to reduced downtime and increased productivity in single screw pipe extrusion processes.

Achieving Stable Output with Efficient Plasticization

In continuous production environments, achieving a Stable Output with Efficient Plasticization is crucial. DEKUMA’s single screw pipe extrusion technology guarantees efficient and uniform melting and plasticization. This consistency is vital for maintaining extrusion linearity, which is essential for producing high-quality pipes. By prioritizing stable output, DEKUMA ensures that its customers can rely on their single screw extruder flexible pipe machines for optimal performance.

Conclusion

DEKUMA’s innovative solutions in single screw pipe extrusion, featuring an intelligent control system and versatile material compatibility, set a new standard in manufacturing efficiency. With a commitment to quality and performance, DEKUMA continues to lead the industry in producing reliable and advanced extrusion machinery.