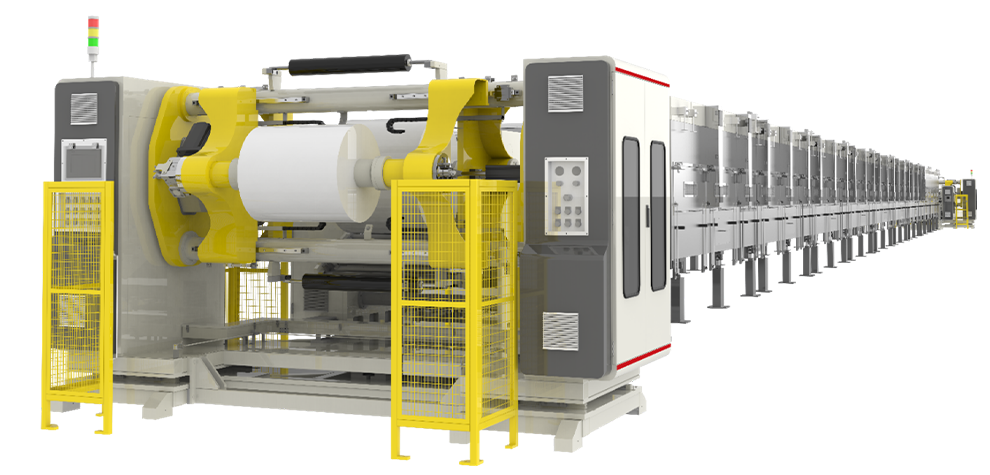

The efficiency of lithium battery production heavily relies on advanced automatic winding machines. These machines play a critical role in the assembly of cylindrical cells, ensuring optimal performance and high-quality output. Understanding the key features of these auto winding machines can help businesses enhance their manufacturing processes and improve overall productivity.

High Speed and Efficiency

One of the standout features of modern winding machines is their speed and efficiency. The 21700 high-speed winding machine, for instance, operates at an impressive capacity of 40 pieces per minute (PPM). This level of output significantly increases production rates compared to manual winding processes. By streamlining the winding operation, companies can better meet market demands and capitalize on growing opportunities within the lithium battery sector.

Precision in Manufacturing

Precision is paramount in the production of lithium battery components, and auto winding machines excel in this aspect. The 21700 high-speed winding machine maintains a yield rate of over 99.8%. This exceptional accuracy minimizes waste and ensures that each cell meets stringent quality standards. The machine features advanced technology that unwinds and corrects the deviation of cathode and anode sheets, followed by ultrasonic welding and taping. Such precise operations are crucial for the integrity and performance of the finished batteries.

Integrated Quality Control

Auto winding machines also incorporate integrated quality control measures that enhance production reliability. The incorporation of CCD surface defect detection allows for real-time monitoring of the winding process, identifying any potential issues before they escalate. By ensuring that only defect-free products move forward in the manufacturing process, companies can maintain high-quality standards and reduce costly rework or recalls.

Elevate Your Operations with Yinghe

For manufacturers looking to upgrade their production capabilities, investing in an advanced winding machine like the 21700 high-speed model from Yinghe can be transformative. Yinghe specializes in developing cutting-edge battery manufacturing equipment designed to boost efficiency, precision, and quality. By partnering with Yinghe, businesses can secure a competitive edge in the rapidly evolving battery market, ensuring their products meet both consumer demand and industry standards.